National Maxi make mechanical press

Single frame casting with 4 tie-rods for rigidity

Wide body design to accomodate large parts

3-station Die-Holder for multiple operation in the press

National Maxi make mechanical press

Single frame casting with 4 tie-rods for rigidity

Wide body design to accomodate large parts

3-station Die-Holder for multiple operation in the press

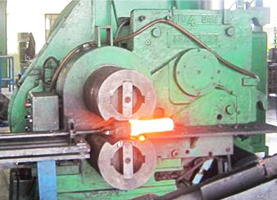

Inductotherm make

Efficient heating

Minimum scale loss

Capability of heating 45mm ~ 80mm diameter

Auto Hi & Low temperature dropout

National make #4 Roll

4 pass design

70mm max diameter

Material weight optimization

Material flow optimization

Wilkins Mitchel make mechanical press

4-Connecting Rod design for better parallelism between ram and bed

Wide ram design suited for trimming and padding operations

Tooling designed to accommodate variety of parts

8mt long conveyor with VFD drive

Suitable for control cooling of micro-alloy steels

Wiremesh chain to minimize nick marks on parts

5CuFt capacity

500 kg/hr blasting capacity

Rubber belt to minimize nick marks

2500Amp machine

Capable of AC & FWDC magnetization

Demag with safety light indicator

Automatic Head/Coil magnetization

High Speed VMC for machining of Dies

All dies & auxiliary tooling can be manufactured in-house

Tooling developed

Programming support available

Cutoff machine

Polishing/Grinding machine

Mounting Press

1000x Microscope with imaging facility

5mm Ball - 750Kgf

10mm Ball-3000Kgf

Surface Plate

Digital Height Gauge

Vernier Calipers

Bevel protractor

Snap gauges